top of page

All Posts

The Safety Analysis Toolbox for Mission-Critical Systems

During the development of mission-critical systems, safety risks emerge at different stages of the system lifecycle. No single safety analysis can address all of these risks. Instead, an effective safety strategy relies on a combination of safety analyses. The selection of appropriate analyses depends on the stage of the project, the information available at that point, and the types of issues or failure mechanisms that need to be identified. Some of the most common analyses

Anunay Krishnamurthy

Jan 126 min read

Sensible Use of AI in Safety-Critical Applications

The Promise and Peril of AI in Engineering Artificial Intelligence (AI) is transforming how engineers work. From automating routine documentation to analyzing complex datasets, AI tools - particularly Large Language Models (LLMs) - offer remarkable productivity gains. According to industry surveys, over 40% of automotive professionals now use AI in some capacity for vehicle design, and this number continues to grow. However, for functional safety engineers, the question isn'

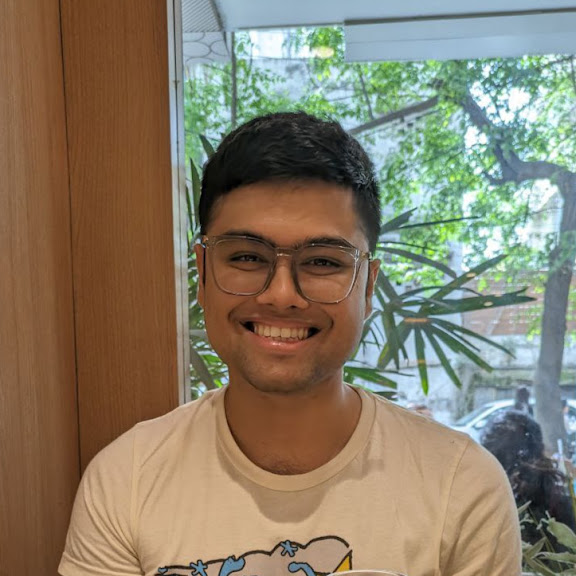

Andrei Biswas

Dec 26, 20255 min read

Memory Safety in Mission-Critical Embedded Software - Part 1

How memory management can turn into real safety hazards In mission-critical embedded systems, think automotive ECUs, avionics controllers, medical devices, industrial safety PLCs, memory safety is not a “nice-to-have.” It’s a reliability and safety requirement. A single memory bug can cause a watchdog reset, corrupt sensor readings, flip a state machine into the wrong mode, or silently degrade behavior over time. In safety terms, that means a software defect can become a ha

Koushik Diwakaruni

Dec 22, 20256 min read

Why Python Struggles in Safety-Critical Embedded Systems

What are Embedded Systems? Before diving into Python's role, let's establish what embedded systems actually are. An embedded system is a specialized computer designed to perform specific tasks within a larger system. Unlike your laptop or smartphone, which runs many different applications, an embedded system typically does one job and does it reliably for years. You'll find embedded systems everywhere: in your car's braking system, your microwave, medical devices, and industr

Andrei Biswas

Dec 12, 20255 min read

SLIKWORKS - modern tool for Functional Safety development

Why do we need modern tools for functional safety? Product development in safety-critical industries such as automotive, aerospace, and robotics is no longer confined to a single team or location. Engineers, developers, and safety experts often work across different countries, time zones, and organizations. As of early 2025, safety engineering work has shifted to one that is increasingly hybrid, where 52% of such employees are working in a hybrid/remote manner. To function e

Anunay Krishnamurthy

Dec 9, 20254 min read

Functional Safety - Examples in everyday life - Elevator System

In everyday life, we rely on countless machines in our office, shopping centers, and even the machines in our homes. When these machines malfunction, they can lead to safety hazards. That’s why they are designed with functional safety in mind: to ensure that if something goes wrong, the machine either fails safely or continues operating in a safe state. Here are a few examples of functional safety we encounter every day: Functional Safety of an Elevator system Elevators are o

Anunay Krishnamurthy

Nov 28, 20253 min read

Use Case 1: ISO 26262 for Powertrain

Powertrain in Electric Vehicles In this example, we’ll look at how functional safety applies to the powertrain system of an electric vehicle (EV), providing a practical view of how ISO 26262 can be implemented. In an EV, the High voltage battery pack supplies electrical power to the electric motor when the driver requests movement through the accelerator pedal. As the driver presses the pedal, sensors detect its position and send this information to a centralized computer, wh

Anunay Krishnamurthy

Nov 11, 20254 min read

Functional Safety - Overview of ISO 26262

What is ISO 26262? ISO 26262 is an international standard for the functional safety of electrical and electronic (E/E) systems in road vehicles. It ensures that E/E systems in road vehicle - cars, trucks, and motorcycles remain safe even when faults occur. The standard defines a risk-based approach using Automotive Safety Integrity Levels (ASILs) to classify hazards, evaluate the risk of hazards, and methods to mitigate risks - from concept and design to production, operation

Anunay Krishnamurthy

Oct 31, 20253 min read

FMEA Challenges and Solving it Using AI - FMEA Series Chapter 3

Challenges while performing an FMEA While the FMEA is a powerful technique to identify gaps in design, engineers frequently encounter challenges during its creation. Some of these challenges include spending too much time creating an FMEA form sheet from an architecture, often extending to a few weeks; spending too much time spent in repetitive tasks like filling out effects, cause and mitigation for similar failure modes; establishing consistency in severity, occurrence

Anunay Krishnamurthy

Oct 22, 20253 min read

FMEA Process and How to Perform an FMEA? FMEA Series Chapter 2

7-step FMEA process The AIAG & VDA FMEA handbook recommends a 7-step process to create FMEA, which is illustrated in the figure below. Figure 1: Overview of the AIAG & VDA FMEA process Step 1 – Planning and Preparation involves defining the purpose of performing the FMEA, assembling a cross-functional team, selecting appropriate tools, establishing a timeline, and setting guidelines for the analysis. The first task is to determine the type of FMEA to be conducted, whe

Anunay Krishnamurthy

Oct 22, 20253 min read

Functional Safety Analysis using FMEA - FMEA series Chapter 1

Understanding FMEA (Failure Mode Effect Analyses): The Cornerstone of Automotive Safety Analysis In the automotive industry, safety is paramount. Every sensor, processor, actuator, and software must work safely to ensure that vehicles operate safely under all conditions. Among the many processes that engineers use to achieve this, the FMEA stands out as one of the most widely adopted and useful methods for identifying and mitigating risk. FMEA background The Failure Mode

Anunay Krishnamurthy

Oct 21, 20254 min read

Which functional safety standards should I follow?

How to choose functional safety standards for a product? To ensure that a product is free from unreasonable safety-related risks, it is recommended to develop it in compliance with state-of-the-art safety standards. However, with numerous standards available, adhering to all of them is neither practical nor necessary. Instead, it is important to identify and adopt the most relevant standards based on the product’s intended application. The applicable functional safety stan

Anunay Krishnamurthy

Oct 21, 20254 min read

bottom of page